JVS CAPABILITIES

Production made easy

180k

Kitchen Towels Daily

240K

Miles Yarn Spun Per Day

180k+

Kitchen Towels Daily

240k+

Miles Yarn Spun Per Day

We pride ourselves on delivering fast, secure, and scalable manufacturing solutions across the globe with unmatched reliability.

FLEXIBLE PROCESSES TO MEET GLOBAL STANDARDS

Full-spectrum manufacturing under one roof

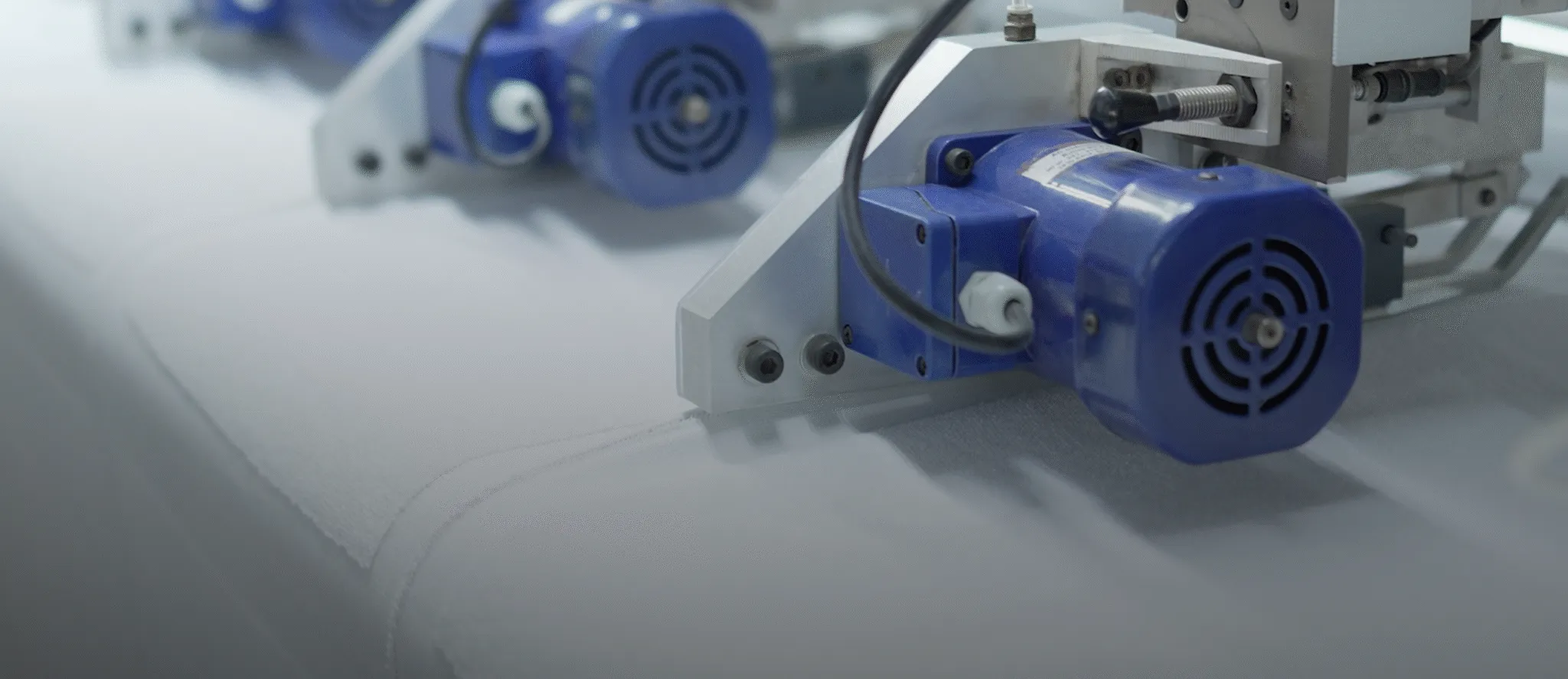

Spinning is where precision begins. We carefully select fibers and control every stage of yarn production to ensure strength, softness, and consistency across all textile categories.

The capacity of yarn spun per day is around 240,000 miles – which is equivalent to the distance from Earth to Moon.

Using advanced looms and meticulous calibration, our weaving process allows for a variety of patterns, weights, and finishes, tailored to the unique needs of each client. Every yard is quality-checked for consistency, strength, and style.

We weave around 40,000 meters of fabric per day – which is equivalent to cover 800 – Olympic sizes swimming pools.

Our dyeing facility blends art and science to deliver rich, even, and lasting color across every fabric.

Wet process per day covers 1600 – Olympic sized swimming pools

From detailed logos to full-panel patterns, our printing capabilities bring designs to life.

We offer rotary, screen, and digital printing techniques to ensure perfect alignment, crisp visuals, and full-color accuracy across every run.

From sample runs to mass production, every piece is shaped, sewn, and finished with care.

180,000 kitchen towels per day

Whether flat-packed, folded, or custom-branded, our team ensures your products arrive looking polished and protected.

With 11 factories, and creating jobs for 1000’s of families, this in-house model minimizes delays, enhances consistency, and allows for greater customization across product categories.

Quality checked at every step

We take quality seriously at every level—from raw material testing to final inspection. Our process combines manual reviews with technology-supported quality checks to ensure consistency in sizing, stitching, color, and finish.

Every product shipped reflects the standards our partners expect from a global supplier.

ACCOUNTABILITY IN ACTION